Page Contents

Details: DR.3D ABS-Like 3D Printer Resin, LCD UV Fast Curing Resin, 405nm Photopolymer Drillable Resin for LCD 3D Printing,1000g White

Brand: DR.3D

Printing Tips Wavelength:365nm-405nmViscosity (cps@25℃:300-400Density (g/cm3): 1.1-1.2Volume shrinkage%: 5-6Linear shrinkage %: 0.8-1.2Hardness (D): 85dTensile strength (Mpa) :35-40Tensile modulus Mpa) :280-350Elongation at break (%):35-40 FAST CURING ABS-Like Resin Slice Setting Recommended print settings: Curing depth DP (mm): 0.05-0.02Printing layer thickness range (mm): 0.05-0.02Curing speed (Ec Mj/cm2): 5.5 2K Printer Bottom exposure time/sec:80-120sExposure time per layer/sec:6-10S 4K Printer Bottom exposure time/sec:30-80sExposure time per layer/sec:2-6S Read more Stress-strain curves ABS-Like resins simulate a range of injection-molded plastics to provide engineers with a wide choice of material properties for prototyping, testing, and manufacturing. Can be drilled without cracking ABS-Like resin has the highest impact strength and elongation at break compared to the other 3D materials. High precision and low shrinkage rate ABS resin has excellent engineering characteristics,which keep the size of the prints is same with the design drawing. Read more Read more Standard Resin Standard Resin Water Washable Resin High Clear Resin ABS-Like Resin High Precision ✓ ✓ ✓ ✓ ✓ Toughness Rigid Rigid Rigid ✓ ✓ Hardness 95D 95D 95D 85D 90D

Advantages

- Products can be returned

- Make sure this fits by entering your model number.

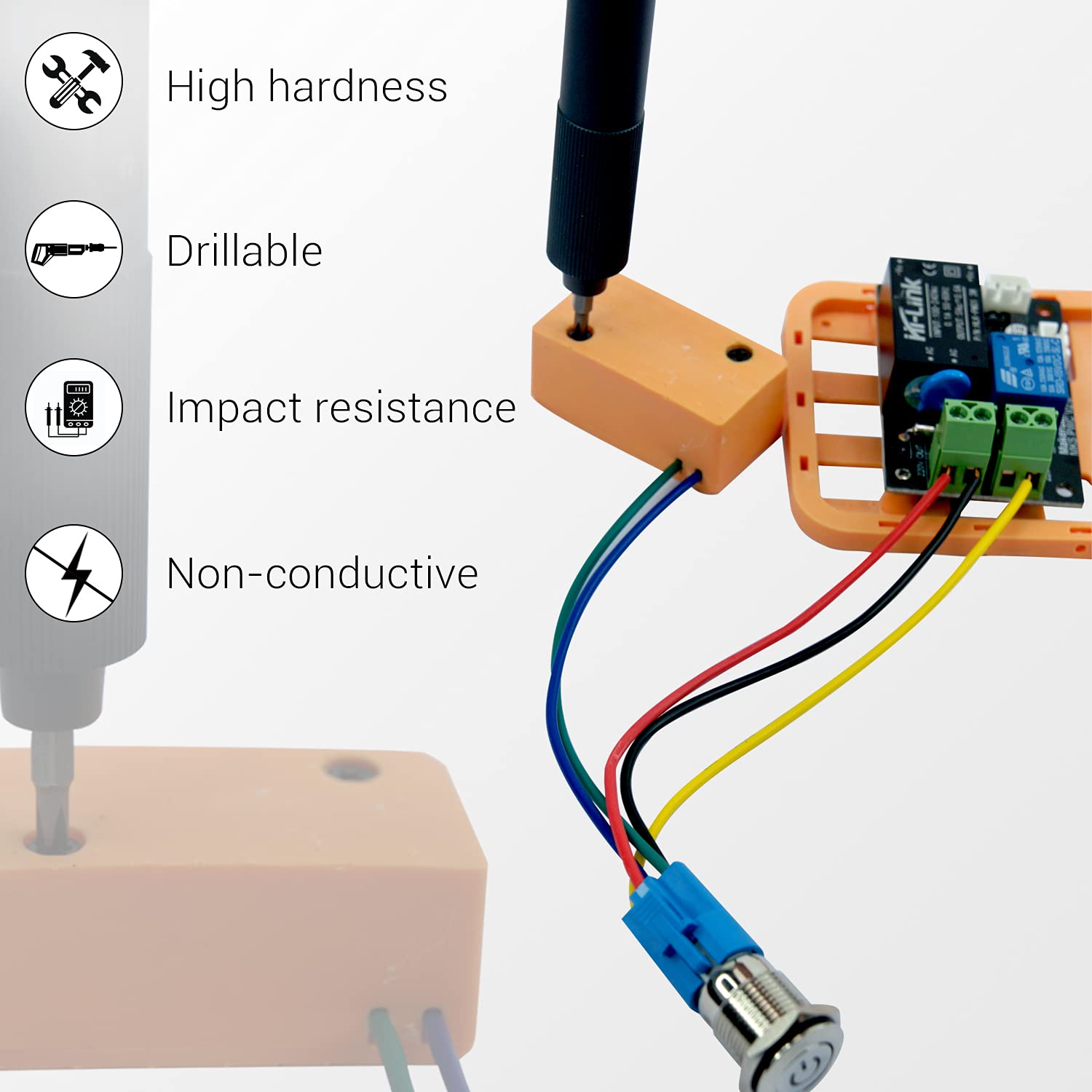

- 【Less odor & High hardness】After a special process, the DR.3D resin is barely no smell during the 3d printing, and the printed model owns high hardness, which can be used to make engineering prints.

- 【Nice Toughness】DR.3D ABS-like resin can print model with high precision, low shrinkage rate; printes works with nice toughness, not brittle, can be drilled, suitable to print wear-resistant industrial parts.

- 【Superior Printing Accuracy】: With the characteristics of low shrinkage, DR.3D 405nm resin will keep the 3D prints in a stable size . You can get a exquisite 3D work with clear, smooth surface details and high strength.

- 【Fast Curing】DR.3D ABS-like 3D resin backflow well due to the low density, which keeps model curing fast during the 3D printing.

Notice

- Is an online purchase

- Delivery may be delayed in some areas.

Buyer Guide 3D Printing Supplies

Buying good 3D printers is a complicated process. There are dozens of factors to consider, and it’s almost impossible for a consumer to vet them on their own.- Price. 3D printers are expensive. The entry-level models start at around US$500, while high-end models cost as much as US$1,500.

- Build Quality. 3D printers are made up of multiple components, and not all of them are created equal. Make sure you pick a model that includes quality components.

- Type of Filament. 3D printer filaments come in different materials. The most common ones include PLA (polylactic acid), ABS (acrylonitrile butadiene styrene), PETG (polyethylene terephthalate glycol), and PVA (polyvinyl alcohol).

- Resolution. 3D printers are more accurate now than ever, but not all of them come with mind-blowing resolutions. Some are capable of printing in resolutions as high as 10 microns (?m).

- Speed. 3D printers are fast. The top models can print objects at speeds of up to 220mm/s.

- Size. 3D printers come in different sizes, from desktop models to industrial-scale solutions. Look up the dimensions of each model.

How to choose 3D Printing Supplies

If you are interested in learning more about 3D printing, you may have already started shopping for the materials and tools you’ll need to create the objects you want.- 3D printing is the process by which a three-dimensional object is created one layer at a time. There are six different types of 3D printing materials to choose from:

- The filament: This is the material, such as plastic, metal, or ceramics, that is fed into a 3D printer.

- Thermal resistance: This refers to how resistant a material is to heat. Some materials, such as PLA, are more thermally sensitive.

- The layer thickness: The layer thickness of the material determines how dense the surface can be. The higher the number, the thicker the layer.

- The curing speed: This refers to how long it takes for a material to solidify.

- The bonding strength: This is the ability of the material to stick to itself or to another object.

Stability: This refers to how resistant a material is to warping or shrinking. Some materials, such as ABS, are more elastic.

When choosing your materials, it’s important to consider which items you plan to print. The printing process requires certain materials like resin, which can be toxic and flammable.

In addition to the materials, you will also want to consider the tools you will need. A 3D printer itself can cost several thousand dollars, so it’s important to choose wisely.

- The size of the printer: When choosing a printer, it’s important to consider the size of the object you plan to print.

- The printing speed: Depending on your needs, you may need a faster or slower printer.

- The resolution: The resolution refers to the level of detail you can include in your print.

- The printing volume: The bigger the printer, the more material it can process at a time.

- The filament capacity: If you plan to print bigger objects, you may need a bigger capacity.

How to maintain 3D Printing Supplies

3D printing is a new technology that is changing the way people create and engineer new products.- To clean the filament, use soap and water to wet your filament, then wipe it dry with a paper towel.

- To clean the nozzles, wipe them with a damp rag.

- To clean the build plate, wipe it with a clean, lint-free cloth.

- To clean the extruder, use compressed air.

- To clean the build plate, first, remove any building material or part from the plate. Then, use a paper towel or paper towel moistened with rubbing alcohol to wipe off the build plate.

- To clean the extruder, first, unplug the extruder from the 3D printer. Then, moisten a paper towel or paper towel with rubbing alcohol and wipe down the extruder.

- To clean the 3D printer, use compressed air to blow loose dust out of the printer.

- To clean the filament, use compressed air to blow loose dust out of the filament.

- To clean the nozzle, use compressed air to blow loose dust out of the nozzle.

- To clean the build plate, use compressed air to blow loose dust out of the build plate.

- To clean the extruder, use compressed air to blow loose dust out of the extruder.

- To clean the filament, unplug the extruder from the 3D printer and use compressed air to blow loose dust out of the filament.

- To clean the nozzle, unplug the nozzle from the 3D printer and use compressed air to blow loose dust out of the nozzle.