Page Contents

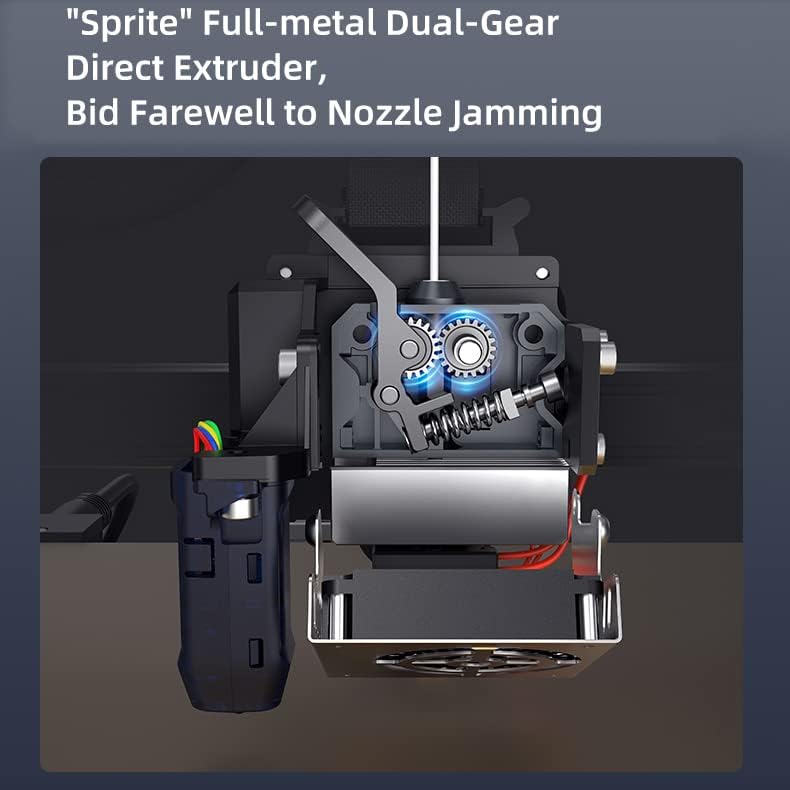

Details: Official Creality Ender 3 S1 Pro Direct Drive FDM 3D Printers with Auto Leveling Bed, 300℃ high Temperature hotend, Filament Sensor, Spring Steel PEI Magnetic Build Plate, Printing Size 220x220x270mm

Brand: Creality 3D

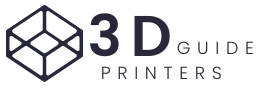

Product Parameters Molding Technolog: FDM Extruder: “Sprite” full-metal dual-gear direct extruder Build Volume: 220 x 220 x 270 mm Printing Speed: Maximum 150 mm/s Printing Precision: +0.1 mm Layer Height: 0.05-0.4mm Filament Diameter: 1.75 mm Nozzle Diameter: 0.4 mm Nozzle Temperature: Up to 300°C Heat Bed Temperature: Up to 110°C Resume Printing: Yes Filament Sensor: Yes Supported Filament: PLA, ABS, WOOD, TPU, PETG, PAS Slicing Software: Creality Slicer/Cura/Repetier-Host/Simplify3D Data Transmission Method: Type-C USB/ SD card 3D File Format: stl/. obj / .gcode (after slicing)

Advantages

- Products can be returned

- Make sure this fits by entering your model number.

- 【”Sprite” Direct Dual-gear Extruder】Creality Ender-3 S1 Pro 3D Printer Equipped Brand-new self-developed “Sprite” direct dual-gear extruder features two chrome steel gears . The extruder realizes smooth feeding and discharging of filaments without slipping and works extremely well in printing flexible filaments such as TPU. Compared with other direct extruders, the “Sprite” is lighter and features less inertia and more precise positioning.

- 【CR Touch AUTO-Leveling bed 】Ender 3 S1 3D printer is equipped with CR Touch Sensor, which is indepently developed. The intelligent leveling system can automatically compensate the error height (accuracy ±0.04mm) at different points of the printing bed, which effectively improves the model printing quality and printing success rate, and makes leveling bed more easily more precise.

- 【Filament Breakage Detecting and Power Off Resume Printing】Ender-3 S1 Pro features the function of detecting filament runout or breakage/power loss and resume printing after recovery. By accurately recording the printing data at the time of power outage/filament runout or breakage, it helps to avoid the waste of filaments and time caused by accidents.

- 【High-precision Dual Z-Axis Higher Printing Precision】With a Z-axis dual-screw+Z-axis dual-motor design, Ender 3S1 Pro works smoother and more synchronously to lower the possibility of lines and ridges on the sides of your print, thus improving the printing quality.

Notice

- Is an online purchase

- Delivery may be delayed in some areas.

Buyer Guide 3D Printers

3D Printers offer users the ability to create physical objects from digital files. Buying the right 3D Printer can be a daunting task and this guide is here to help you make the right decision.- Budget. Budget is the biggest factor that should guide your buying decision. While a low-end printer may suffice for most users, the difference in print quality between a low-end and a high-end printer may not be worth the added cost.

- Nozzle Size. Nozzle size determines the size of the nozzle tip. A larger nozzle tip prints finer details, but requires more time to print. The tradeoff is that printing a large object may require more material.

- Filament Diameter. The filament diameter determines the diameter of the extruded thread. The thinner the filament the better the resolution, but the larger the print. The bigger the print, the longer it takes to print.

- Print Speed. Print speed determines how fast the printer can print, measured in mm/s. Higher print speeds allow you to print larger objects in a short time.

- Nozzle Change Time. The nozzle change will determine how quickly you can replace a nozzle tip. Changing a nozzle tip with a slow change time means you need to wait for the printer to cool down before you can replace the nozzle tip.

How to choose 3D Printers

Although 3D printers may be new to you, they’re actually already very commonplace.- 3D Printers can take many forms. The most commonly used types of 3D printers are desktop printers, which are relatively small, and Industrial printers, which are larger and more powerful. Desktop 3D printers are less expensive and easier to use, but Industrial printers are generally sturdier and can take on larger jobs.

- 3D Printers use a variety of materials to print. The most common type of 3D printer uses plastic filament, which can be molded into a variety of shapes. Filament comes in a variety of colors and can be used to make a variety of objects, including smartphone cases, laptop cases, and toys.

- 3D Printers can be used for any purpose. Whether you want to make sculptures, furniture, or parts for your own do-it-yourself projects, 3D printers can help you create any 3D object you have in mind.

- 3D Printers are not a magic bullet. As with any new technology, 3D printers have pros and cons. While 3D printers are less expensive and easier to use than traditional manufacturing, they require special CAD software, which can cost thousands of dollars. 3D printers also dont offer the same range of materials, and cant create as many complex shapes as traditional manufacturing.

- 3D printers have advantages. If youre short on time or money, 3D printers can be a great solution, especially for small projects or limited budgets. 3D printing is also useful for prototyping and can help you quickly create and sell your own products.

How to maintain 3D Printers

3D printing is a remarkable way to create complex, functional objects. However, 3D printing is also incredibly time-consuming, complicated, and expensive.Because of this, many 3D printers require regular maintenance. For instance, most 3D printers have a nozzle, which can get clogged with debris over time.

These clogs can slow down your prints, cause jams and errors, and ruin the quality of your 3D creations.

There are countless tutorials and guides on how to unclog a 3D printer’s nozzle. However, many of these guides require expensive replacement parts or professional equipment.

Luckily, there are several ways to clean your 3D printer’s nozzle without purchasing expensive replacement parts. Some of the most common ways to clean a 3D printer’s nozzle are:

- Cleaning the nozzle with alcohol.

- Cleaning the nozzle with dish soap.

- Installing a UV lamp.

- Cleaning the nozzle with a toothbrush.

- Using a rotating brush.

- Using compressed air to blow away debris.